Table Of Content

If your duct sizing is too big, the velocity will be compromised, meaning you may not be able to feel it through the air vents. That deduction gives you the available static pressure (ASP), or static pressure budget, you’re working with when designing the duct system. You cannot exceed the ASP or the system will deliver improper airflow and cause equipment problems over time.

The velocity reduction method can be used when sizing air ducts.

With these considerations in place we can come back to the duct design. So if you’re an engineer, designer, architect or just someone interested in trying out simulation technology, then I highly recommend you check this software out, get your free account by following this link. In order to display all the necessary data, these calculators are best viewed on a laptop or desktop computer; sorry, but they are not mobile-friendly without zooming in and panning around. While it may be impossible to create a calculator that is both simple and all encompassing.

Insert air ducts to your Sketchup model with the Engineering ToolBox Sketchup Extension

Auxiliary ventilation systems in mining and tunnelling: Air leakage prediction and system design to optimize the energy ... - ScienceDirect.com

Auxiliary ventilation systems in mining and tunnelling: Air leakage prediction and system design to optimize the energy ....

Posted: Thu, 29 Jun 2023 14:43:39 GMT [source]

A duct sizing chart relies foremost on the square footage of a home or office space—but, more importantly, the size of each individual room within the building. Too large or too small HVAC ductwork sizing can cause problems similar to what happens when technicians install an improperly sized HVAC unit. To check for accurate measurements, many techs rely on HVAC duct sizing calculator free tools, such as a ductulator. Mastering the calculation of air velocity in duct systems is an essential skill for efficient HVAC design and maintenance.

Sizing Your Home’s Square Footage

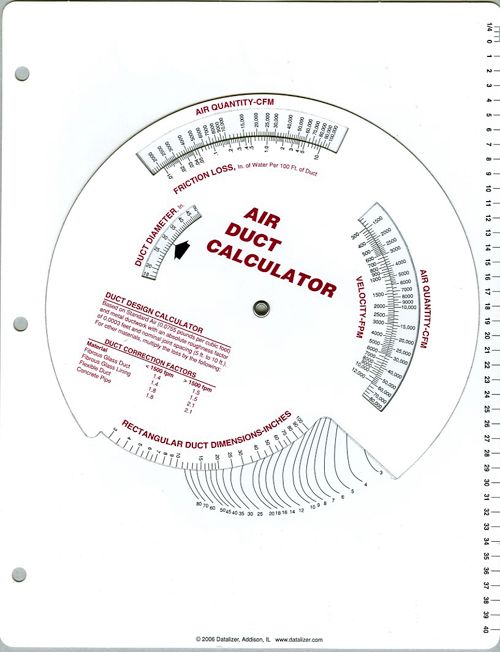

Users can input air velocity, friction factor, or duct dimensions to obtain the required duct size. Mechanical engineers, HVAC designers, contractors, and technicians can all benefit from this tool. It simplifies the complex process of duct sizing, allowing professionals to optimize airflow, ensure efficient performance, and comply with industry standards and regulations. Friction rate (FR) helps you decide the diameter and shape of ductwork you can use without negatively impacting optimal air flow. It’s calculated by using the available static pressure (ASP) divided by total effective length (TEL) and multiplied by 100 to show how much pressure drop the system can accommodate per 100 feet of effective length. You want a higher friction rate, because it means you can use smaller, more restrictive ductwork than on an HVAC project designed with a lower friction rate, which requires larger ducts.

This allows the air to smoothly change direction and thus there is no sudden increase in static pressure and the air flow rate to the rooms has dramatically increased. The second thing to consider is the material being used for the ducts, and the roughness of this material as this causes friction. For example, if we had two ducts, with equal dimensions, volume flow rate and velocity, the only difference is the material. One is made from standard galvanised steel the other from fibreglass, the pressure drop over a 10m distance for this example, is around 11 Pa for the galvanised steel and 16 Pa for the Fibreglass. This free ductulator calculates the exact duct size (round and rectangular) for the given friction rate, duct type, and amount of airflow. It will automatically adjust the size to keep from exceeding the maximum Manual D velocities for residential duct systems.

Over the years, these principles have been applied and refined by engineers in the field of HVAC to ensure effective and efficient air distribution systems. Although you are most likely fine with the external static pressure, it is good to double check just in case you stretched the duct too long. However, if you are not dealing with multiple rooms, you may choose to use free return that doesn’t require any return duct. Basically, you use the space above the ceiling as a plenum for return air. Then, at the end of the branch duct, I use an end cap instead of a butterfly fitting.

Spiral duct manufacturer introduces calculator app 2017-07-01 SNIPS Magazine - ACHR NEWS

Spiral duct manufacturer introduces calculator app 2017-07-01 SNIPS Magazine.

Posted: Sat, 01 Jul 2017 07:00:00 GMT [source]

If professional services are required, please consult a licensed professional engineer in your location, as building codes differ based on differing jurisdictions. The author and publisher shall not be liable in the event of damages of any kind in connection with, or arising from, the use of the information contained within this website. Still, you should always at least consult with a knowledgeable professional when you’re designing an HVAC duct system. The size of your ductwork can massively alter the comfort of your home—and the amount you spend every month to keep your house heated or cooled. HVAC units represent the largest portion of your home’s energy use, so getting those numbers right is imperative in order to save the most money on utility bills.

Finally, we want to consider adding a fresh air duct and check the static pressure in the duct system. Keep in mind, duct material choice also affects airflow resistance and static pressure, therefore calculations for flexible duct sizing differ slightly from sheet metal ductwork. Flex duct CFM will measure less than the airflow in sheet metal and for coated fiberglass duct board. Flex duct CFM changes based on how it’s installed, with performance drastically reduced if not completely stretched out, or with sharp turns and twists.

Different systems may have different velocity requirements based on their specific design and intended use. The calculation principle remains the same, but the duct area formula differs. H2x simplifies the design process for engineers, enabling them to create top-notch designs efficiently while ensuring compliance with industry standards. H2x is a design tool built to ensure compliance, efficiency, accuracy and collaboration.

Determining the correct tonnage HVAC unit and designing a residential duct system hasn't got to be complicated. In the guide we will break the process down and walk you through the steps necessary to design efficient climate control solutions. Now find the total duct losses for each duct and branch, that’s very easy to do simply multiply the duct length by the pressure drop per meter, in our example we found it to be 0.65pa/m. We know all the values for this so we can calculate the mass flow rate (how many kilograms per second of air needs to enter the room). If we look at the calculation for room 1, we see it requires 0.26 kg/s. So we just repeat that calculation for the rest of the room to find all the mass flow rates.

Then we can calculate the dynamic loss for the air which turns into the bend. Then we find the area ratio using the formula diameter out squared divided by diameter in squared. We take our values from our table and use 3.5m/s divided by 4m/s to get 0.875 for the velocity ratio and we use 0.26m squared divided by 0.33m squared to get 0.62 for the area ratio. Now we calculate the dynamic loss for the straight path through the tee, using the formula co multiplied by rho multiplied by v squared divided by 2. If we drop our values in we get the answer of 0.934 pascals so add that to the table. In the guides we find two tables the one you use depends on the direction of flow, we’re using the straight direction so we locate that one and then look up each ratio to find our loss coefficient.

For that, you can see my post Supply Air Diffuser Sizing Guide (Practical Selection). The engineer(s) designing these calculators use their best efforts to provide accurate results. Adicot, Inc. makes no warranty of any kind, expressed or implied, concerning the information contained on this website. The information presented on this website shall be used by professionals who understand the implications of the results.

This is because an additional branch now feeds the three smaller branches allowing some of the air to smoothly break away from the main flow and feed into these smaller branches. The sharp turns cause a large amount of recirculation regions within the ducts, preventing the air from moving smoothly. In other words, we know that a BTU ducted air conditioner has a fan strong enough to push through 0.17 in.WG of friction and deliver air at the farthest supply air diffuser. Once you are done with the main duct, branch ducts and flexible ducts, indicate their sizes on the layout drawing so that it is easier for you to request a quotation or do the costing.

For rooms that aren’t perfectly square or rectangular, such as an L-shaped space, split the room into sections and total the area of each section. While DIY ductwork sizing gives you a good estimate of what you need, it makes sense to have an experienced HVAC contractor give you a second opinion. Our free estimate tool can help you can at least 3 local quotes in a minute. Because the layout of most ductwork systems fit into the “normal” range, and our calculator factors for that already. Each fitting is rated with a number representing the amount of friction it causes in feet of ductwork equivalency.

No comments:

Post a Comment